Operations Support

Pipeline Integrity

Pipeline safety is our passion. When quality, experience and cost matter you can turn to our powerhouse integrity and compliance team.

What Is Pipeline Integrity?

The process of pipeline integrity ensures pipelines and their related components are properly and safely designed and operational. The goal is to safeguard pipelines from damage and defects all the way through their life spans, from design to decommissioning.

Because pipelines are exposed to extreme conditions, taking steps to improve and maintain pipeline integrity is essential. As a result, pipeline integrity management (PIM) involves numerous strategies to ensure the pipeline is continually safe for use.

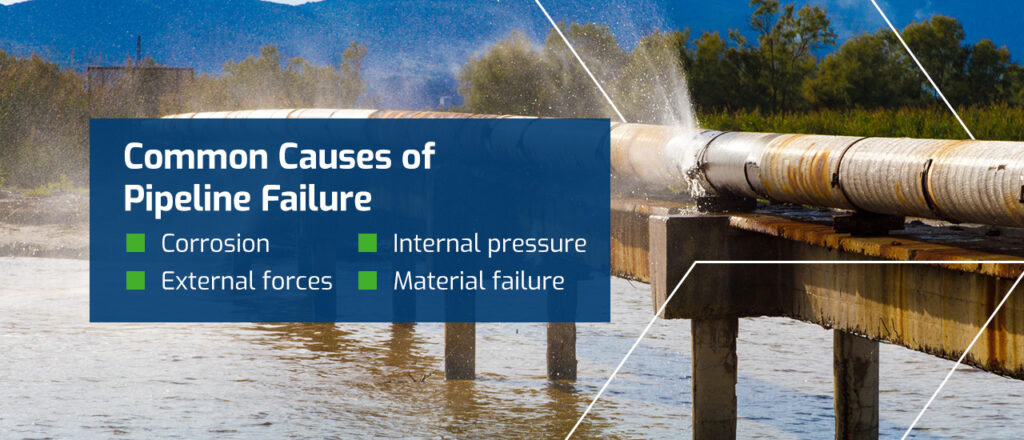

Common Causes of Pipeline Failure

Understanding how a pipeline might fail is crucial, as it helps pipeline managers and maintenance workers better anticipate failures and enact proper PIM. There are several potential causes of pipeline failure, including:

- Corrosion: This process happens naturally when metal materials deteriorate through oxidation. In regard to pipelines, corrosion can cause metal loss in the pipe, which leads to weakening and compromises the overall integrity of the pipe. There are two main types of corrosion — external, which is the outside material of the pipe reacting with the surrounding environment, and internal, which refers to interior pipe corrosion from the products traveling through it. Other specific types of corrosion can occur on pipeline components, such as seam corrosion.

- External forces: One of the most common pipeline failure causes is external damage. For example, natural forces like landslides or temperature extremes, or other outside forces, such as vandalism, can lead to failures in pipeline integrity. These causes can be beyond human control, but PIM for external forces is still necessary.

- Internal pressure: The internal pressure within pipelines is often cyclical, which can lead to eventual interior wear. This kind of failure is more likely to happen over time as the inner wall of the pipe experiences pressure fluctuations.

- Material failure: Sometimes, defects can be present in the material manufacturing process for pipelines. This issue can lead to incomplete bonding in the steel components used to produce the pipe. While rare in modern pipeline production processes, impurities are still a possibility and can lead to failure later on.

Understanding how a pipeline might fail is crucial, as it helps pipeline managers and maintenance workers better anticipate failures and enact proper PIM.

Assurance That Critical Infrastructure Is Safe and Reliable

Pipeline integrity management ensures safety from conception to retirement. Our integrity management services include program development, data validation, risk analysis, corrosion evaluation, integrity engineering and integrity field services.

TRC’s experienced pipeline integrity team will get you in the rule and keep you in the rule. Not satisfied with standardized pipeline integrity solutions? Our experts provide carefully tailored integrity strategies that solve your specific challenges within your corporate framework and budget.

The need for accurate comprehensive analysis of integrity data is of the utmost importance to ensure you can make informed and accurate decisions about safely operating and maintaining your assets.

Integrity Engineering:

- HCA and MCA Identification and Class Locations Analysis (Gas)

- HCA Spill Modeling and Air Dispersion (Liquids)

- Emergency Flow Restricting Device (EFRD) Studies

- MAOP/MOP Calculation, Validation and Reconfirmation

- Pipeline and Facility Risk and Threat Identification

- In-Line Inspection (ILI) Program, Design and Implementation

- Remediation Planning

Integrity Field Services:

- ILI Program Management Including Repair and Remediation

- Integrity Dig Plan Development and Management

- ILI Tool Validation and Run Supervision

- Non-Destructive Testing (NDT) Services Including Validation

- Line Location and Structure Validation

- Asset and Class Location Verification

- Digital Field Data Capture

Corrosion Services:

- Direct Assessment Program Design and Management (ECDA, ICDA and SCCDA)

- CP Design and AC Mitigation

- Model Pipeline and HVAC Powerlines

- Close Interval Survey and Corrosion Mapping

- Coating Assessment

- MIC Sample Collection

- Test Stations, External Corrosion Coupons, Reference Cells and Anodes

Related Materials

Pipeline Integrity and Engineering

Published 05.11.2021

Pipeline and Facility Risk Assessment

Published 03.11.2024

AC Influence Assessment and Cathodic Protection Services

Published 02.29.2024

Direct Assessment and Non-Destructive Examination

Published 02.05.2020

Gas Mega Rule

Published 02.29.2024

ILI for Integrity Engineering

Published 02.05.2020

Integrity Management Services

Published 03.14.2024

Structure Validation & Asset Verification

Published 02.29.2024

GIS for Pipelines

Published 02.29.2024

Operator Qualification Services

Published 02.08.2021

Emergency Planning and Response

Published 03.15.2021

Engineering Critical Assessment

Published 03.14.2024

TSA Pipeline Cybersecurity Services

Published 06.03.2021

Augmented Reality Headset for Field Teams

Published 10.28.2021

PHMSA Grant Program Support for Municipalities

Published 12.02.2021

Looking for effective pipeline integrity services?

Turn to the experts at TRC.